Development & Adaptation

When demanded by our customers we develop and produce completely customised solutions. We target several industries although our background is in the commercial vehicle segment. Our development projects are therefore performed according to automotive standards (APQP) and our production is certified according to ISO 9001, ISO 14001 and IATF 16949.

Example of Development:

Climate Control Panel for City Bus

Complete responsibility for development of electrical hardware and software. Mechanical parts by our design and all production tools such as for injection moulding sourced by our team. PCB-A and final assembly in our in-house production as well as laser etching of the symbols. At EOL a computerised test of each unit including emulation of communication with the vehicle’s CAN bus.

Example of Development:

Electronic Relay for Marine Engine

For toughest possible environment we developed this rugged electronic relay. Electronics is encapsulated in potting to achieve IP69 protection. In our in-house production we do PCB-assembly, potting, final assembly and a computerised end of line test.

Example of Adaptation:

Programming of Current Sensor

Standard current sensor reprogrammed in our facilities to meet customer demands of specific CAN baud rate, address etc.

Example of Adaptation:

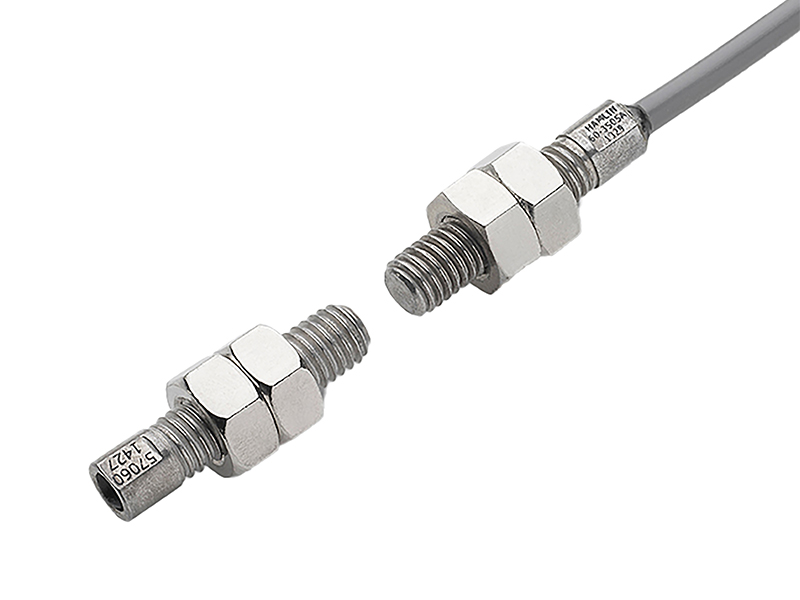

Customised Harness for Reed Switch

For our customer we identified a suitable off-the-shelf reed switch to detect if hatch is open or closed on a bus. To facilitate proper connection to vehicle ECU we add a customised cable harness before delivering to our customer. We also deliver together with suitable magnet to activate the switch.